The Power of Data Visualization Using Tableau

Generative AI in Supply Chain: The Path to Increasing ROI

Imagine a supply chain that could predict disruptions, automate decisions, and turn data into insights instantly. This isn’t a glimpse into the distant future; it’s the power of generative AI in supply chain today.

As businesses grapple with increasing complexity and a shrinking talent pool, smarter solutions have become the need of the hour. Generative AI enters as a savior here, emerging as the key to unlocking unprecedented efficiency and innovation.

But how can companies move beyond the AI hype and utilize its true potential?

Let’s explore how Generative AI is reshaping supply chains with streamlined workflows and how businesses can tap into its potential.

Importance of Generative AI in the Supply Chain Management

Generative AI is facilitating massive shifts in distribution networks from rigid, linear operations to dynamic, interconnected ecosystems. Unlike conventional AI solutions, it introduces groundbreaking capabilities that drive agility, intelligence, and strategic value across the entire distribution network.

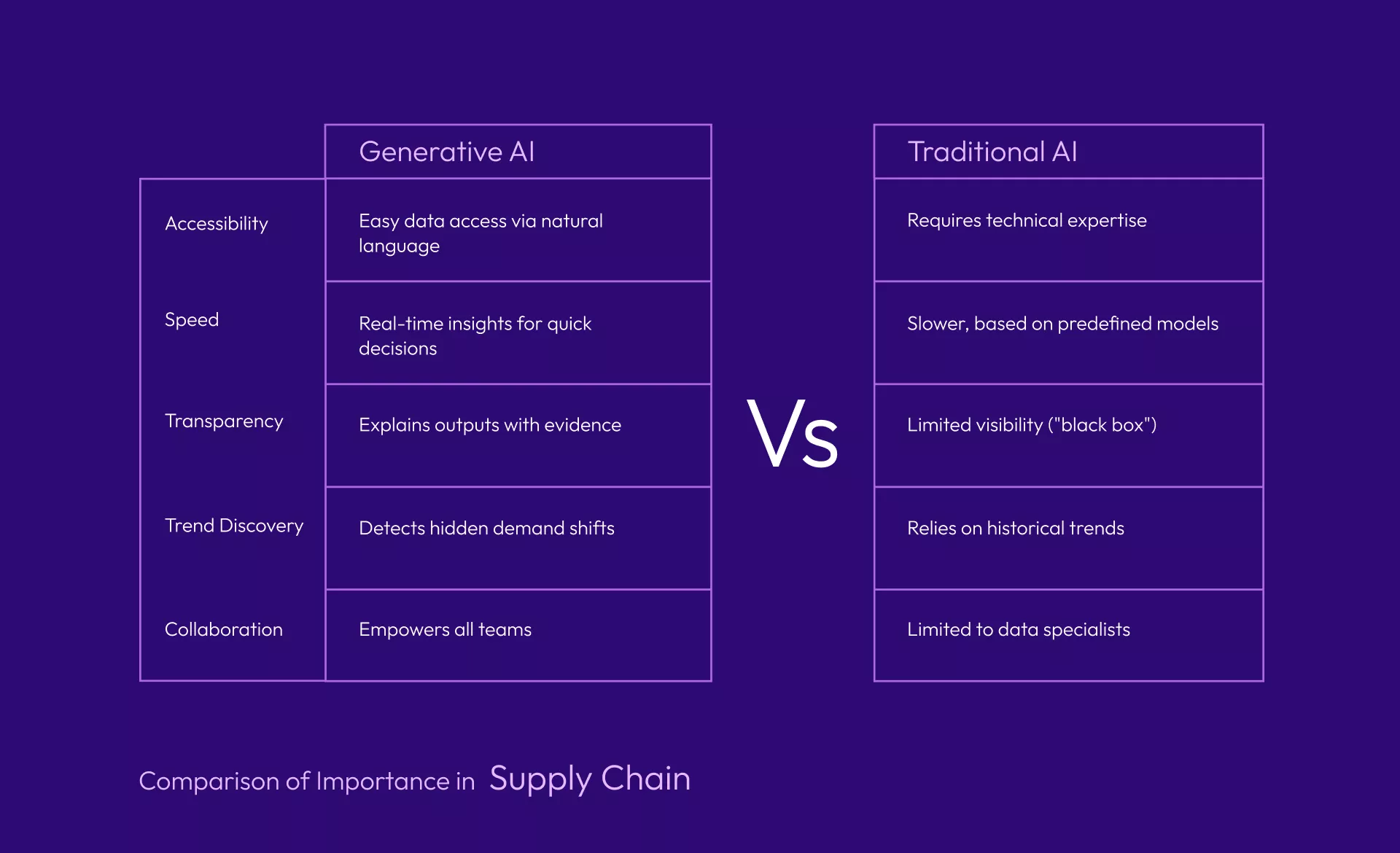

How Generative AI Takes It a Notch Above Traditional AI in Supply Chain Automation

Often mistaken for traditional AI, Generative AI goes a step further by making data more accessible, transparent, and actionable for all users. Its advantages include:

- Enhanced Accessibility: Natural language interfaces allow non-technical users to query data and interpret insights effortlessly, reducing reliance on specialized teams.

- Faster Decision-Making: Generative AI in the supply chain synthesizes complex data quickly, enabling real-time responses to challenges.

- Improved Transparency: It explains machine learning outputs with evidence packages, fostering greater trust and understanding of AI-driven decisions.

- Hidden Trend Discovery: Unveils demand patterns and shifts that traditional AI may overlook, providing deeper insights.

- Broader Engagement: Empowers diverse teams to collaborate and participate in data-driven strategies, democratizing decision-making processes.

By streamlining workflows, boosting collaboration, and driving innovation, generative AI offers a transformative edge over traditional AI in modern distribution chain management.

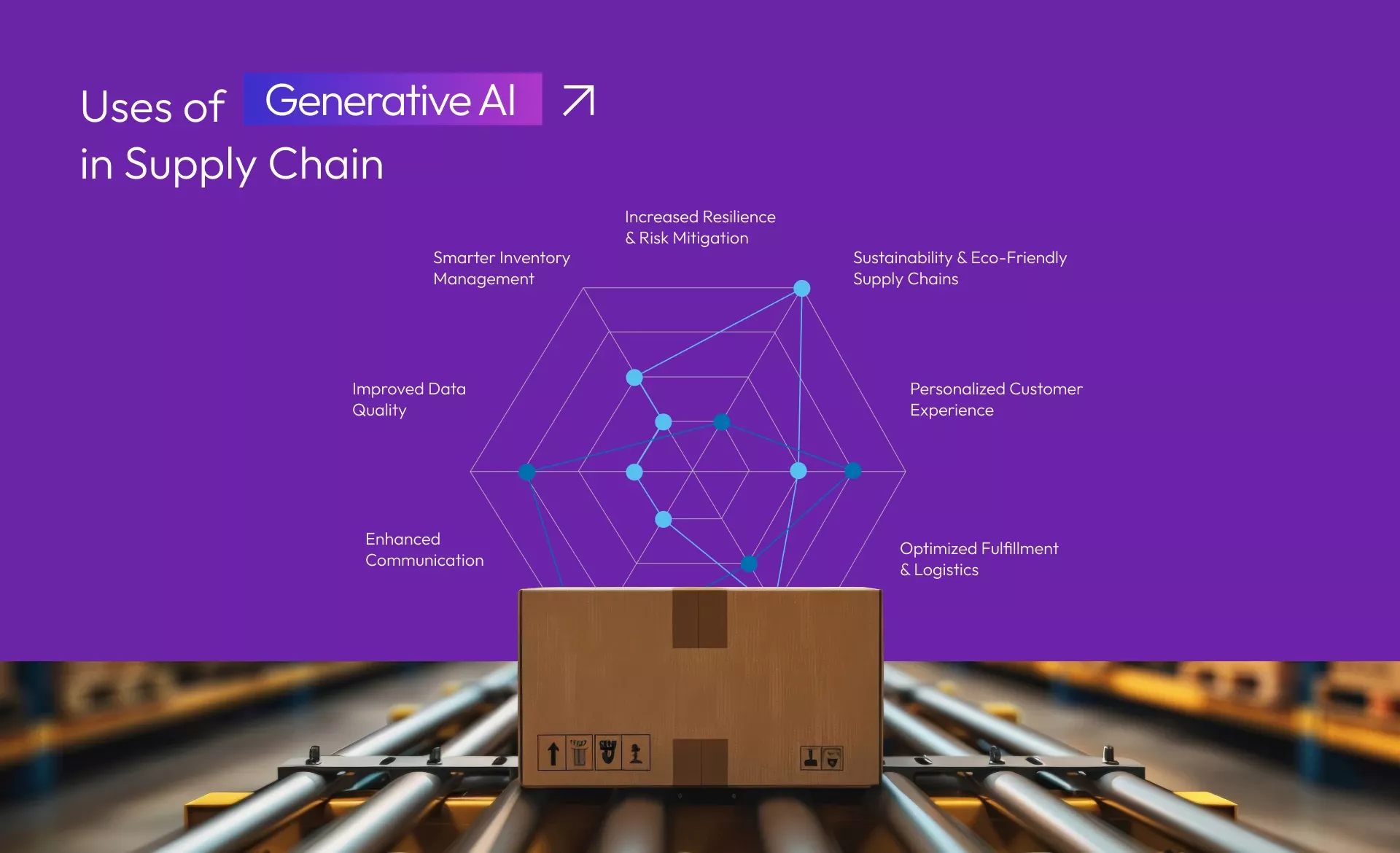

How Is Generative AI Used in Supply Chain?

Generative AI acts as a powerful collaborator, augmenting human expertise to improve decision-making in the trade chain.

Find out the areas in which it improves outcomes in the supply-to-distribution chain.

Enhanced Communication

Generative AI in the supply chain simplifies global collaboration by breaking language barriers and facilitating seamless communication.

- AI-powered translation tools help trading partners communicate effectively across different languages.

- Chatbots can summarize lengthy documents, draft professional emails, and generate responses to customer inquiries, ensuring clarity and efficiency.

For instance, AI-driven tools can create multilingual purchase agreements, allowing international suppliers and buyers to interact without misunderstandings.

Improved Data Quality

Maintaining accurate and complete data is critical for operations in the supply network. Generative AI enhances data quality by:

- Detecting anomalies in datasets through pattern recognition.

- Fill in missing information and enhance product descriptions.

- Identifying and correcting errors before data is shared with stakeholders.

To understand how to use generative AI in procurement, look at ecommerce platforms that can use Generative AI to automatically identify discrepancies in product pricing or specifications. This can prevent costly procurement mistakes and ensure consistency across databases.

Smarter Inventory Management

Managing inventory efficiently requires precise demand forecasting and stock optimization, which can be done by using Generative AI for:

- Generating predictive models that analyze historical sales data to anticipate fluctuations in supply and demand to anticipate demand and optimize stock levels.

- Recommending restocking strategies to maintain optimal inventory levels, reducing the risks of stockouts or overstocking based on historical sales data.

One of the best generative AI in supply chain examples in efficient inventory management is reducing wastage in the food industry.

Generative AI can analyze seasonal trends and suggest adjusting inventory levels accordingly, ensuring that businesses always have the right products available at the right time.

Increased Resilience & Risk Mitigation

Disruptions in the trade chain can have significant financial and operational impacts. Generative AI enhances resilience by:

- Creating digital twins or virtual simulations of distribution networks that test various disruption scenarios

- Predicting potential risks by analyzing historical data on weather patterns, labor strikes, and logistical bottlenecks and recommending proactive solutions.

For example, if a port strike is expected to delay shipments, AI can suggest alternative transportation routes to minimize disruptions and maintain smooth operations.

Sustainability & Eco-Friendly Supply Chains

Sustainability is a growing priority for businesses, and Generative AI plays a key role in reducing environmental impact.

AI can:

- Suggest eco-friendly materials for product design, minimizing waste in packaging.

- Optimize distribution routes to lower carbon emissions.

For example, AI can analyze supplier networks and recommend alternative vendors that use sustainable raw materials, contributing to greener trade operations in manufacturing. Additionally, AI-driven logistics planning can reduce fuel consumption by selecting the most efficient transportation methods.

Personalized Customer Experience

Generative AI in the supply chain enhances customer engagement by delivering highly personalized experiences.

- It learns from user interactions, refines recommendations, and tailors product offerings based on customer preferences.

- By analyzing purchase history and behavioral patterns, AI can suggest personalized product bundles that align with individual needs.

Utilizing these benefits, generative AI in healthcare supply chain can optimize medication inventory management, ensuring timely availability and enhancing patient care.

Optimized Fulfillment & Logistics

Efficiency in logistics and fulfillment is crucial for timely deliveries. Generative AI in supply chain optimizes fulfillment processes by:

- Analyzing real-time data to generate the most efficient delivery routes.

- Dynamically adjusting fulfillment strategies based on customer demand and market conditions.

For instance, AI can identify traffic congestion or extreme weather conditions and recommend rerouting shipments to ensure on-time delivery. By continuously learning from past data, AI improves decision-making and enhances agility in the logistics network.

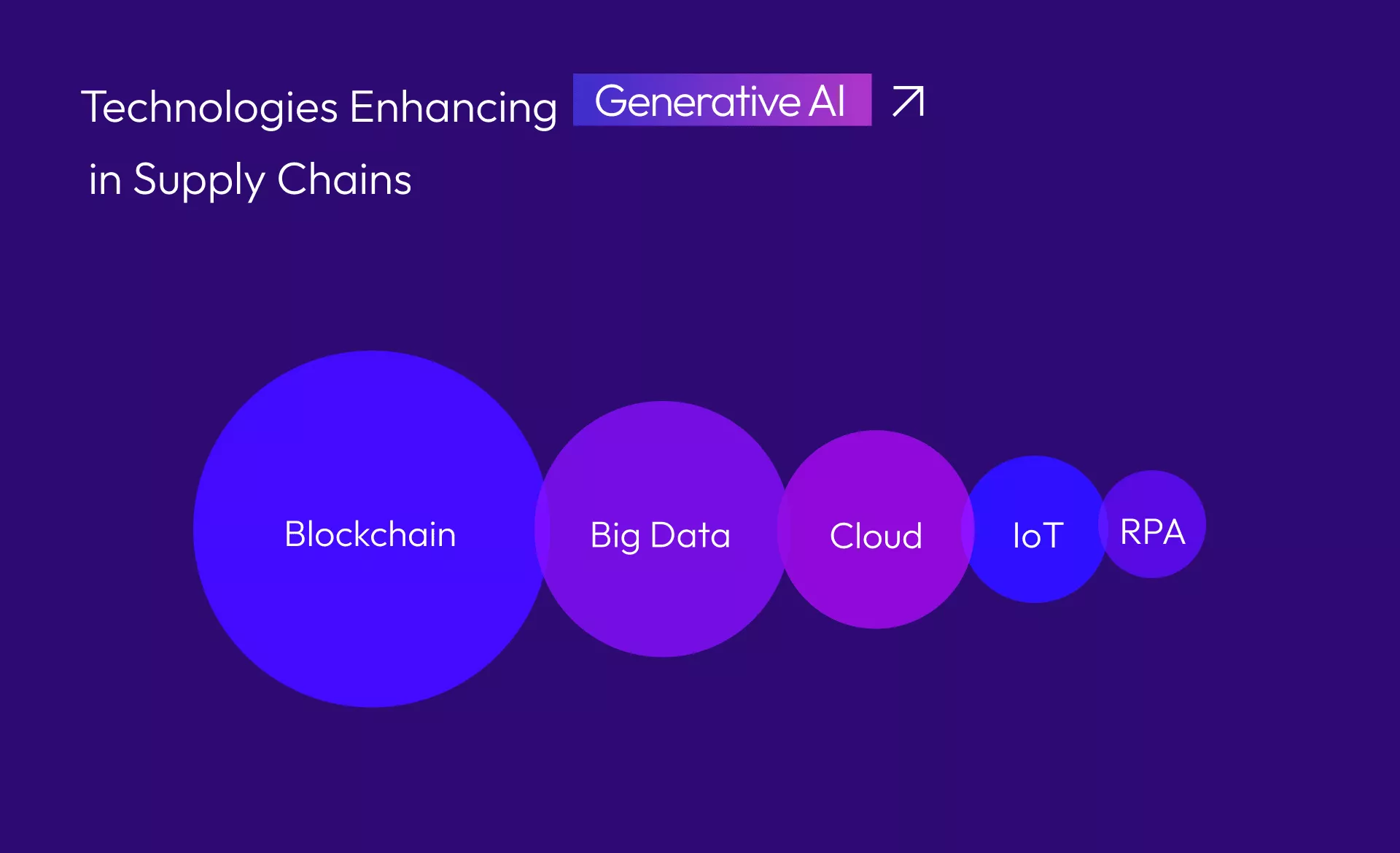

Technologies Enhancing Generative AI Capabilities in Supply Chains

IoT (Internet of Things)

IoT sensors provide real-time data on inventory, shipments, and equipment, enabling AI to optimize logistics, detect inefficiencies, and automate responses. For example, cold chain logistics use IoT to track temperature-sensitive goods, preventing spoilage.

Robotic Process Automation (RPA)

RPA complements generative AI in supply chain by automating business workflows. It does so by handling routine tasks like order processing and invoicing, working alongside AI for faster, error-free operations. For example, AI-driven demand forecasts can trigger automated procurement orders via RPA.

Blockchain

Blockchain ensures secure, transparent distribution of data, preventing fraud and improving compliance. AI-generated supplier recommendations can be verified through blockchain, ensuring ethical sourcing and regulatory adherence.

Big Data Analytics

AI leverages Big Data from sources like transaction histories and social media to improve demand forecasting and logistics using analytics. For instance, AI can analyze consumer sentiment to predict product demand shifts.

Cloud Computing

Cloud computing provides on-demand infrastructure for AI-driven supply chain applications, facilitating real-time collaboration. Retailers can access supplier inventory and logistics data instantly, ensuring seamless operations.

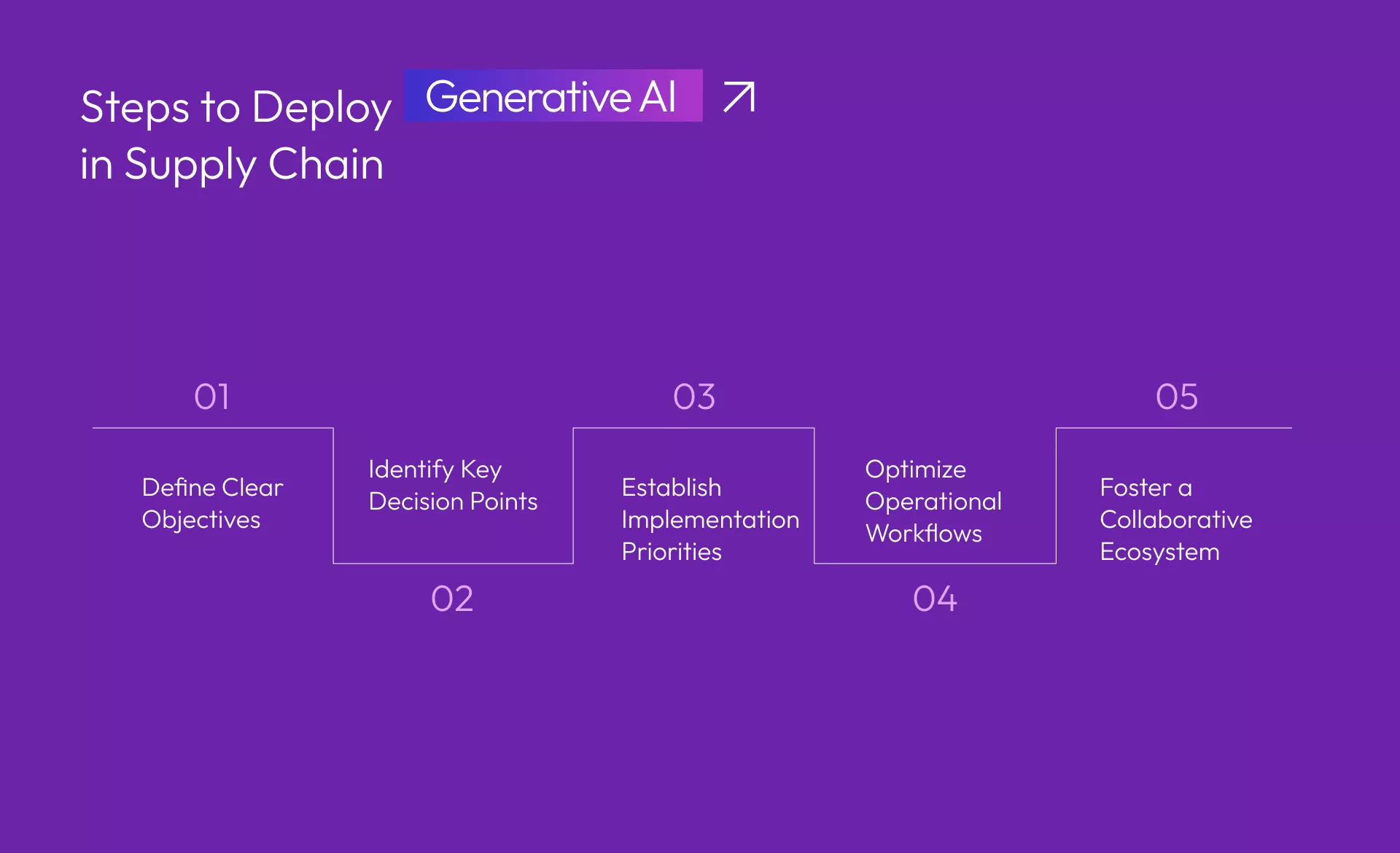

Steps to Deploy Generative AI in Supply Chain

Implementing Generative AI in supply chain operations requires a strategic approach to align technical capabilities with business goals. Follow these five essential steps for a seamless integration:

1. Define Clear Objectives

- Align Generative AI adoption with strategic business goals (e.g., efficiency, cost reduction).

- Assess current capabilities and potential skill gaps.

- Define measurable outcomes to ensure business impact.

2. Identify Key Decision Points

- Pinpoint critical areas where AI can enhance decision-making (e.g., inventory management, production scheduling).

- Focus on areas where AI can enhance speed, accuracy, and efficiency.

- Prioritize high-value areas to maximize returns.

3. Establish Implementation Priorities

- Identify areas with the highest initial impact and ease of implementation.

- Start with automating routine processes for quick wins.

- Build momentum to fund further initiatives driven by generative AI in the supply chain.

4. Optimize Operational Workflows

- Integrate Generative AI into daily operations for better decision-making.

- Shift from human-operated to human-designed workflows.

- Automate repetitive tasks to free up strategic focus.

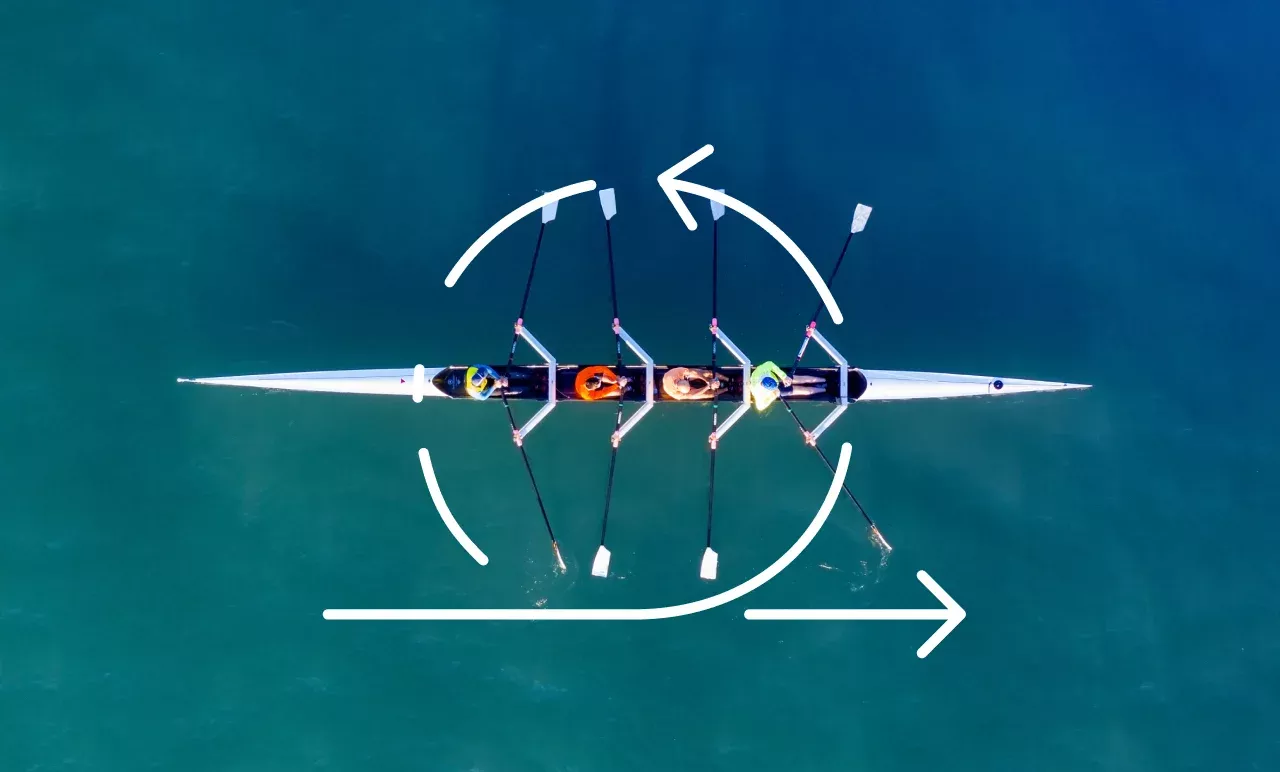

5. Foster a Collaborative Ecosystem

- Collaborate with technology partners and AI specialists.

- Leverage external expertise to fill capability gaps.

- Ensure scalability and access to the latest innovations.

To conclude…

Generative AI in supply chain is not only redefining processes; it is making them smarter, more resilient, and future-ready. By leveraging AI-powered insights, businesses can unlock new efficiencies, reduce risks, and create seamless customer experiences.

Those who embrace this technology will gain a competitive edge in an increasingly complex and dynamic marketplace.

Want to explore how Generative AI can revolutionize your supply chain? Get in touch with our experts today!

Email us or Talk to us at +91-98367-81929 or Simply Contact Us through the website.

Let's Connect