The Power of Data Visualization Using Tableau

The Role of Technology in Manufacturing: Building a Sustainable Future

“Sustainability” has become a buzzword for customers, governments, and businesses alike, as they swiftly implement the latest technology in manufacturing. Jumping onto the wagon are manufacturers too.

A top priority while rethinking the traditional manufacturing processes is decarbonization. It is key to rethinking manufacturing, requiring optimized processes, reduced waste, and eco-friendly materials to achieve net-zero goals.

So, what green manufacturing technologies can companies adopt to achieve their sustainability goals? And, how are these innovations benefiting the global landscape?

Let’s find out.

Addressing Key Challenges in the Manufacturing Sector

Growing Cybersecurity Risks

As manufacturing processes become more interconnected and data-driven, the sector faces escalating cyber threats, surpassing even finance and insurance in the share of global cyberattacks.

The integration of IoT, robotics, AI, and autonomous machines has further expanded the attack surface, raising concerns about data security and potential operational disruptions. Key threats include:

- Phishing Attacks: Malicious emails or fake websites corrupt systems, stealing business data for financial gain.

- Ransomware: Encrypts files, rendering networks inoperable until demands are met, with threats of data leaks.

- Supply Chain Attacks: Exploits weak links in partners' systems, impacting operations across the supply chain.

- IP Theft: Silent harvesting of intellectual property that can lead to stolen or altered data.

Outdated Infrastructure

Manufacturers must address the challenge of outdated, rigid infrastructures that are often incompatible with modern technologies.

Digital transformation requires a comprehensive organizational shift, starting with:

- Training in robotic operations

- Flexible production line configurations

- Cloud-based resource planning

At the same time, establishing a carbon footprint baseline is crucial for sustainability.

While manufacturers often measure direct energy usage, accounting for indirect emissions is challenging.

Automation, cloud computing, and data analytics can help by recording and reporting environmental impact, but many companies still rely on outdated, disconnected systems.

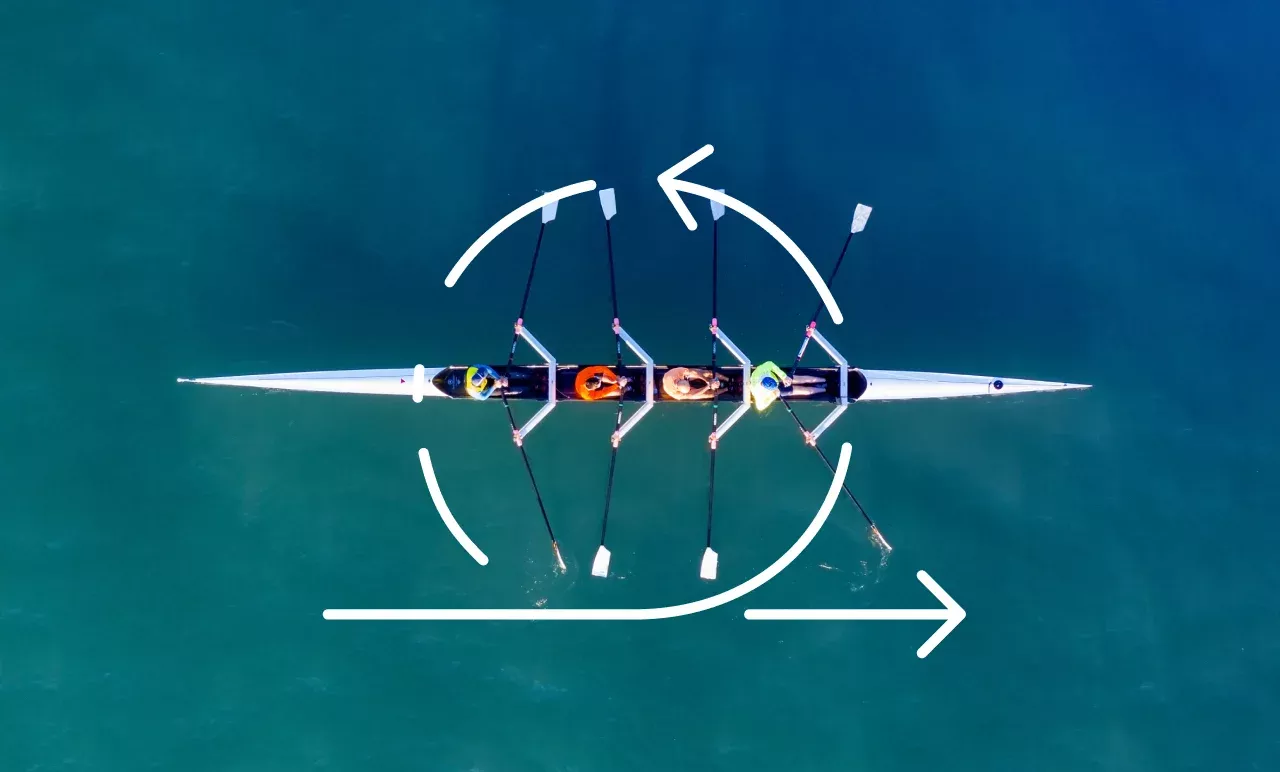

Transitioning to Agile Manufacturing Models

Traditionally, manufacturing stages operated in isolation, causing issues like heavy inventories, wasted hours, and increased costs due to a lack of integration.

Emerging technology models, by contrast, are agile and flexible, enabling rapid adaptation to changing demands.

However, adopting this model requires:

- End-to-end supply chain integration

- Efficiency and agility across all stages, including suppliers

- Open, fast communication within the organization

These shifts demand a new mindset on the assembly line. However, they are often met with resistance from labor and middle management, who may question whether the new approach truly outperforms the traditional model.

Knowledge Gap in Manufacturing Digitization

One of the biggest challenges in manufacturing digitization is the limited expertise needed to safely implement advanced technologies.

Manufacturers must invest in learning to use tools like advanced analytics, AI, machine learning, digital twins, and automation.

Without this knowledge, progress can stall.

For companies without in-house tech teams, outsourcing can ease the adoption process. The process can be further simplified with expert partners like Sundew offering strategic guidance and simplifying the transformation journey.

Human Errors

Human errors are one of the most common challenges in manufacturing digitization, affecting safety, quality, and cybersecurity.

For example, employees may incorrectly configure machines, disclose sensitive information, mishandle equipment, or open unknown attachments.

Additionally, new processes can increase the risk of human error, especially if employees are resistant to change.

To address this, it’s important to highlight the benefits of digitization, empowering employees to identify areas for adaptation and improvement rather than imposing change.

How to Use Technology in Manufacturing for Sustainable Growth?

As environmental awareness rises, consumers are increasingly seeking ways to reduce their impact.

Governments and global organizations are also introducing regulations to ensure manufacturers adopt greener practices.

So, how is technology used in manufacturing to promote more sustainable outcomes?

Here are some key technologies that businesses must implement to stay compliant and future-proof.

Artificial Intelligence (AI)

AI is transforming production efficiency across industries, and its impact on sustainability is equally profound.

For manufacturers, AI integration stands primary in meeting 79% of sustainable development goals. This can be done through robotics, machine learning, or advanced data systems.

Beyond environmental benefits, AI offers manufacturers and their clients substantial business advantages.

By leveraging AI-driven insights, companies can enhance product quality, reduce defects, and minimize downtime from equipment inefficiencies.

The result? Reduced waste, energy savings, and timely delivery of superior products to customers.

Big Data and Analytics

Big data is another technology in manufacturing that enhances both sustainability and productivity.

Advanced big data & analytics systems are transforming how businesses monitor supply chains, predict customer demand, plan operational capacity, and assess environmental impact.

With up to 2,000 pieces of equipment on a single production line, each equipped with 100-200 sensors collecting data every second, the potential for manufacturers is immense. This data enables accurate emissions reporting and rapid identification of efficiency challenges.

Moreover, data sharing promotes innovative collaboration, allowing companies to pool resources, fill capability gaps, and access new markets.

For example, integrating insurance underwriters and telecommunications providers can deliver microinsurance via mobile subscriptions to underserved populations. By harnessing big data, manufacturers can drive sustainable growth while addressing social and environmental issues.

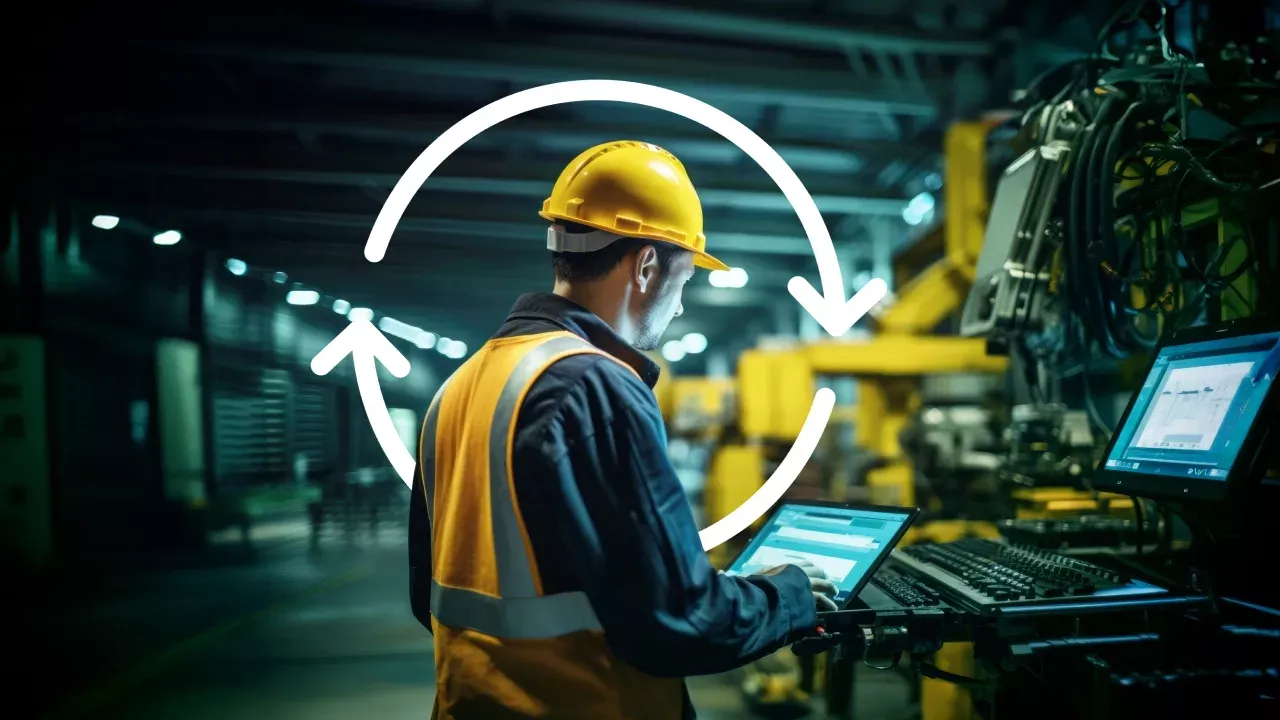

Industrial Internet of Things (IIoT)

Equipping production systems with intelligent technologies allows manufacturers to enhance efficiency and safety, and minimize downtime. A recent ABB survey found that IIoT integration has helped 94% of manufacturers see significant improvements in sustainability.

By connecting machines, manufacturers can monitor performance in real-time, swiftly addressing inefficiencies and preventing costly downtime and waste. Sensors track carbon emissions, providing visibility and traceable metrics for regulation compliance.

Additionally, enhanced waste traceability offers deeper insights into waste management systems.

Ultimately, connecting intelligent machines provides actionable data that helps businesses meet compliance standards. This approach also facilitates more sustainable operations and supply chains.

Enterprise Resource Planning (ERP) Software

ERP systems integrate all major business functions - from accounts and procurement to operations - by collecting and sharing data across the organization. This comprehensive overview helps manufacturers meet compliance standards and achieve end-to-end efficiency.

By providing insights into energy and material consumption, ERPs enable executives to identify opportunities for waste reduction and efficiency gains.

They also facilitate accurate carbon impact estimates, pinpointing areas for minimizing greenhouse gas emissions and driving sustainability.

Benefits of Digital Technology in Manufacturing

Implementing the latest technology in manufacturing companies offers transformative advantages at every stage of the production process. These include the following.

Environmental Conservation

Advanced technologies significantly reduce energy consumption, emissions, and waste, leading to a smaller environmental footprint. By embracing eco-friendly practices, manufacturers help preserve natural resources and address climate change.

Cost Savings

Investing in sustainable technologies often results in long-term cost savings. Energy-efficient machinery lowers utility bills, while waste reduction strategies minimize disposal costs, enhancing overall operational efficiency.

Market Competitiveness

Adopting green manufacturing practices provides a competitive edge as consumers increasingly favor eco-friendly products. This commitment enhances brand reputation and attracts environmentally conscious consumers and talent.

Regulatory Compliance

With stricter environmental regulations, new technology in the manufacturing industry enables companies to meet compliance standards effectively. This proactive approach mitigates legal risks and builds trust among stakeholders.

Increased Productivity

Technologies like additive manufacturing and AI enhance operational efficiency, resulting in higher-quality products and faster response times to market demands. This, in turn, significantly boosts productivity.

Improved Worker Safety

Automation and robotics reduce human exposure to hazards on the production line. Remote monitoring allows workers to focus on complex tasks, enhancing safety and overall well-being.

Greater Resilience

Advanced digital technology in manufacturing promotes enhanced agility in the face of challenges. Companies that leverage these innovations often outperform competitors and adapt better to market changes.

Enhanced Profitability

As eco-conscious consumers prioritize sustainability, businesses aligning with these values can achieve greater market success. Technology helps navigate stricter regulations, ensuring profitability while appealing to a conscientious audience.

Achieving net zero will require reimagining entire ecosystems— using AI integration, IoT, and big data to optimize processes, cut waste, and boost efficiency.

While the challenges may seem daunting, companies worldwide are introducing innovative solutions aimed at preserving the planet for future generations. While addressing the environmental impact of industrialization is a complex and gradual process, it is undoubtedly achievable.

Technology in manufacturing plays a pivotal role in this transformation, delivering scalable and impactful solutions to build a more sustainable future.

Email us or Talk to us at +91-98367-81929 or Simply Contact Us through the website.

Let's Connect